Characteristic advantages:

(1) Energy saving:The press adopts a servo system, with a dual closed loop system for system pressure and flow rate. The hydraulic system supplies oil according to the actual required flow rate and pressure, which overcomes the high energy consumption caused by high-pressure overflow in ordinary quantitative pump systems. During high flow stages such as mold opening, core membrane, and stamping, the motor works at the set speed. During low flow stages such as filling and picking up, the motor speed is reduced, and the actual energy consumption of the oil pump motor is reduced by 25% -65%.

(2) Quick response and high production efficiency:The servo system has a fast response speed, with a pressure rise time and flow rise time of up to 30ms, which improves the response speed of the hydraulic system, reduces the operation conversion time, and accelerates the overall running cycle of the machine; When the hydraulic system of the press is running automatically, when a valve is opened, the system pressure will instantly decrease. The servo system can quickly replenish the oil volume within 30ms, and the pressure will reach the set value.

(3) Stable and precise pressure:The servo system has strong adjustment ability, and the pressure closed-loop control system makes the system pressure very stable. The pressure fluctuation is below+0.5 bar~-0.5 bar, which improves the molding quality of the product.

(4) Low oil temperature rise:The oil temperature of the press increases by 8 ℃~10 ℃ from start-up to steady-state operation. At room temperature of 35 ℃, there is no need for cooling water, and the amount of cooler used is greatly reduced, which extends the life of the entire machine, especially the hydraulic oil and hydraulic vulnerable parts (such as oil seals).

(5) Low noise:The noise of the hydraulic system is within 65dB, which improves the on-site environment for operating the machine.

Technical features:

Output torque: below the rated speed of the motor200%Constant torque output provides conditions for rapid response

2 Position accuracy: The dynamic position accuracy is ±5PThe static position accuracy is ±1P

3 Speed accuracy: ±0.02%Meet the precision requirements of the upper computer control

4 Speed ratio:1:25000Adjust the speed ratio to meet the speed regulation requirements of CNC

5 Acceleration and deceleration:3000Hz/sThe acceleration ensures the responsiveness of the servo

6.Control computation time:<150μsTo provide assurance for precise control and rapid response of motors

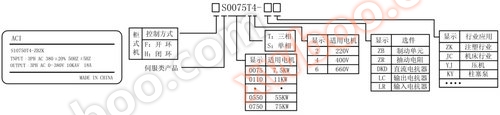

Model description of servo controller:

Company switchboard:

Company Fax: